Precision bending is a critical element of metallic fabrication, plus the purpose of progressive equipment in acquiring significant amounts of accuracy can not be overstated. On the subject of bending advanced styles, gooseneck punches are getting to be indispensable for suppliers relying on CNC push brakes to execute precise operations. Their exclusive style and unparalleled operation have built them a major preference from the field, especially when working with challenging geometries. This blog site will discuss the function of gooseneck punches, their unique design strengths, and why partnering that has a gooseneck punch maker with in-house CNC capabilities is helpful.

Tableof contents:

Understanding the purpose of Gooseneck Punches in CNC push Brakes

How Gooseneck Punch design and style Prevents Material Collision in the course of Bending

Added benefits of selecting a Gooseneck Punch company with In-House CNC Capabilities

comprehending the job of Gooseneck Punches in CNC Press Brakes

Gooseneck punches Enjoy a significant function while in the bending process by providing exceptional versatility and precision. not like common punches, a gooseneck punch is uniquely curved to accommodate sophisticated air bending procedures, allowing suppliers to bend intricate designs with out harming the material or tooling. They can be most often used in CNC push brakes, devices created to bend metallic by forming straight or angled strains. These equipment depend upon compatibility with dependable tooling, and gooseneck punches get noticed for their capability to adapt to intricate kinds.What will make gooseneck punches so sizeable is their capacity to execute bends that could usually be impossible with straight punches. They also help air bending, which utilizes a lot less drive and Strength when compared with bottoming or coining methods. This functional flexibility helps make them a fantastic option for advanced fabrication needs. From architectural parts to engineering sections, the precision offered by gooseneck punches tends to make them a real asset for manufacturers Doing the job in industries that desire exactitude.

How Gooseneck Punch structure helps prevent product Collision During Bending

The trick into the accomplishment of gooseneck punches lies of their intelligent style and design. Their distinct "gooseneck" condition stops collision concerning the punch and previously formed flanges or bends. This is particularly important when manufacturing areas with intricate profiles or substantial, slim flanges That may otherwise interfere with typical punch functions.The curved higher portion of the punch supplies clearance that avoids detrimental the product or Device, making it perfect for predicaments necessitating deep and sophisticated bends. suppliers can reduce high priced generation problems since the material is never compressed or improperly bent. This also enhances performance by getting rid of the need for additional methods, for instance transforming or manually re-aligning the sheet steel. Additionally, the design of gooseneck punches allows far more uniform force distribution over the air bending course of action, which decreases use and tear about the resources and makes certain consistent, large-top quality effects across all output runs. Precision architects, engineers, and assemblies count on this Sophisticated tooling element to drastically improve efficiency without forfeiting top quality.

Benefits of Choosing a Gooseneck Punch producer with In-residence CNC Capabilities

locating a trustworthy gooseneck punch provider with in-dwelling CNC manufacturing capabilities can wholly transform the way in which corporations approach their production procedures. Suppliers that style and design and manufacture their own personal instruments utilizing Innovative CNC technology provide unmatched positive aspects, which include really personalized alternatives, speedier creation instances, and exceptional good quality assurance. By tailoring applications to meet certain bending necessities, these brands make certain that each job is finished with precision and effectiveness. the opportunity to Management the whole generation method less than a person roof also appreciably reduces lead moments, aiding corporations stay away from delays and manage regular productiveness. Additionally, the strict high quality criteria upheld by in-home CNC manufacturers end in tough and large-accomplishing equipment, including induction-hardened gooseneck punches created to face up to demanding circumstances. With their check here unique style and design and ability to deal with intricate bends without substance collision, gooseneck punches are a crucial innovation in precision engineering, featuring companies a strong mixture of reliability, performance, and good quality to elevate their functions.

The developments in precision engineering, exemplified by equipment like induction-hardened gooseneck punches, continue to drive the producing marketplace towards greater efficiency and innovation. By combining longevity, accuracy, and flexibility, these tools permit brands to meet advanced needs although protecting high-quality requirements. In-dwelling CNC manufacturing makes certain that these important elements are crafted to perfection, empowering industries to achieve top-quality outcomes. As know-how progresses, purchasing precision-engineered remedies remains essential for being aggressive and pushing the boundaries of what is possible in fashionable production.

Romeo Miller Then & Now!

Romeo Miller Then & Now! Tatyana Ali Then & Now!

Tatyana Ali Then & Now! Danny Pintauro Then & Now!

Danny Pintauro Then & Now! Elisabeth Shue Then & Now!

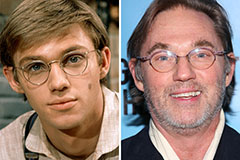

Elisabeth Shue Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now!